Transitioning into Green Hydrogen CHP

Introduction

With 38% of U.S. electricity generation coming from Natural Gas, constituting the highest share among other fuel resources, Green Hydrogen is being looked into as the up-and-coming alternative.

For decades, Natural Gas has been increasingly displacing Coal in the power generation sector, but this correlation is now starting to transition into Green Hydrogen displacing Natural Gas. Several Pilot projects are being deployed in Europe and North America for:

- 100% Green Hydrogen CHP plants mainly led by 2G energy & INNIO.

- Testing and validating Hydrogen Blending in the existing Gas Pipeline infrastructure.

Most of the CHP industry is currently fully dependent on Natural Gas as fuel. However, CHP Manufacturers are acknowledging the Green Hydrogen trend and adapting their products to the new fuel; either in the form of Hydrogen blended with Natural Gas, or 100% Hydrogen ready Packaged CHP products (Green Hydrogen CHP).

Green Hydrogen CHP systems energy viability

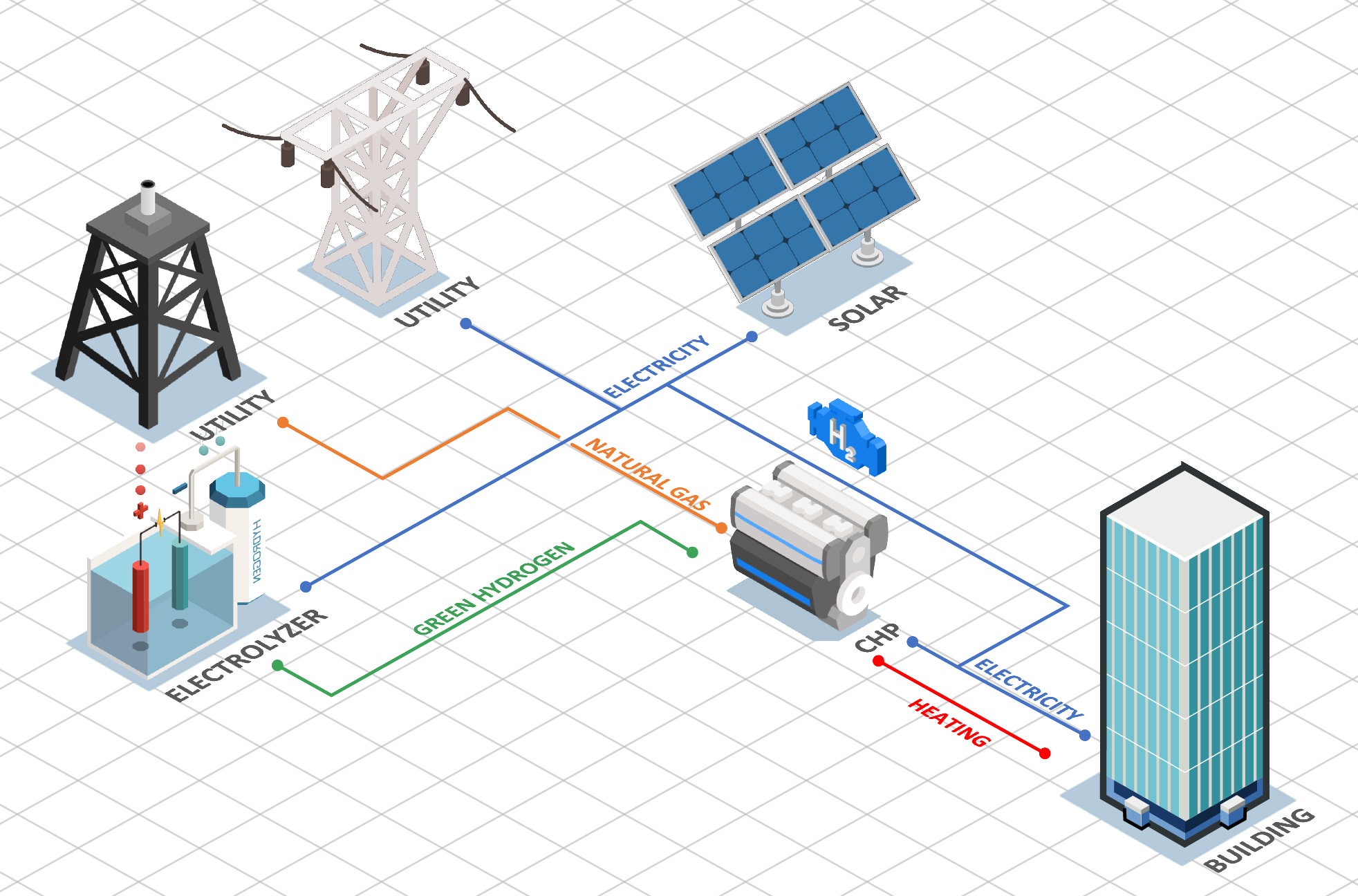

Green Hydrogen CHP System Diagram

Green Hydrogen must be produced from Renewable energy using Electrolyzers (which use electricity to split water molecules into Hydrogen and oxygen); the concept is to take advantage of high production periods of e.g., Solar and Wind Technologies, and instead of storing excess generation into Battery Systems, it is used to produce Hydrogen via Electrolyzers, then stored in pressure vessels, or used directly into Power generation applications, in our case CHP.

The round-trip efficiency of producing electricity and thermal energy from a renewable resource through a Green Hydrogen CHP, could average between 40-60% for small to mid-scale systems (<10MW). So, every 10 kWh of solar energy would provide about 5 kWh of total energy (electricity + thermal). Higher efficiencies (75%-80%) can be achieved at large scale systems (>50MW). Battery Storage Systems can currently provide higher round trip efficiencies (>80%), providing ONLY electric energy. But if separate heating systems (e.g. Boilers and DHW Heaters) efficiencies (average at 80%) are taken into account, the total system efficiency is the same as that of a Green Hydrogen CHP System.

Green Hydrogen cost competitiveness timeline

Current Green Hydrogen prices are high compared to pipeline natural gas, However, “it is expected to fall in the coming years due to cheaper and more efficient Electrolyzers coming to market.” (Source: csis.org).

Examples of Companies currently providing packaged Electrolyzer systems for Green Hydrogen production:

Investments in scaling applications and technologies will eventually drop Hydrogen prices:

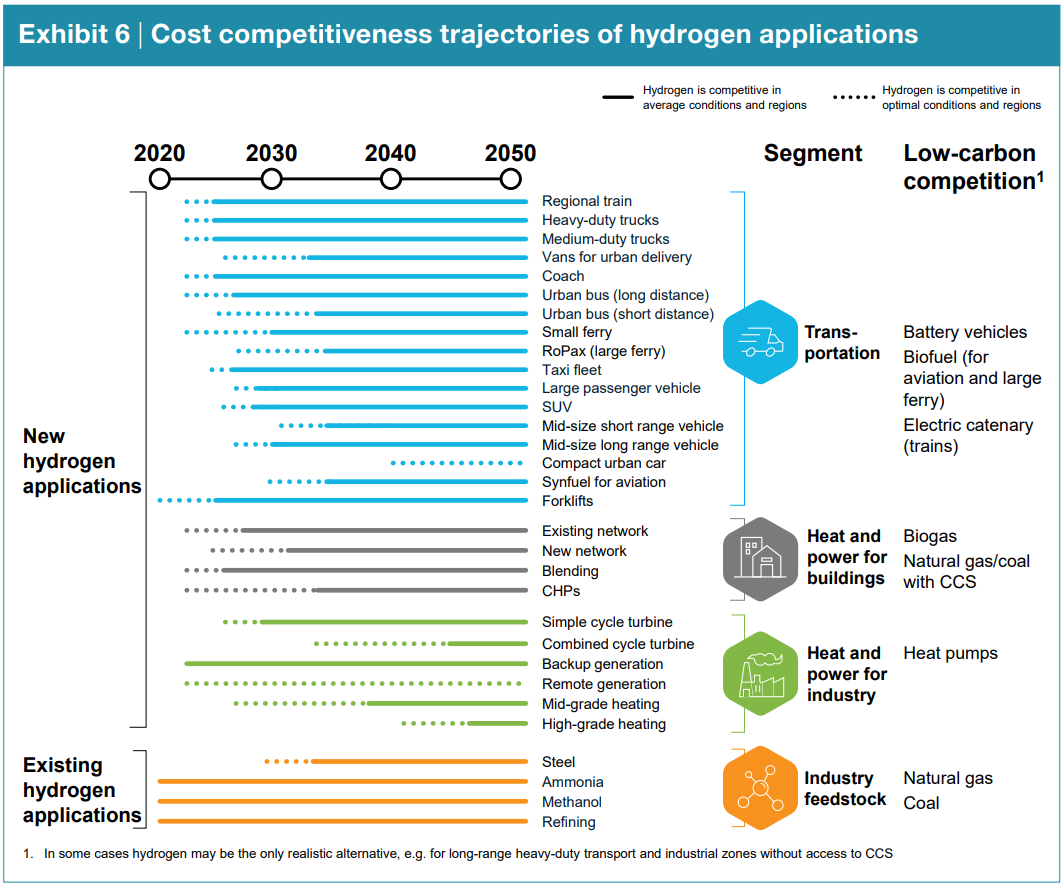

For example, scaling fuel cell production from 10,000 to 200,000 units can reduce unit costs by as much as 45%, irrespective of any major technological breakthroughs, and can impact multiple end-use cases. Scaling up to 70 GW of electrolysis will lead to electrolyser costs of less than USD 400 per kW. Exhibit 6 below shows the point at which hydrogen becomes the most cost-competitive low-carbon solution for each application. The break-even timing depends heavily on the region, each of which has its own energy prices, infrastructure readiness, and available policy framework to support scale-up and regulation. The dashes in the exhibit show when an application becomes cost competitive in all regions analyzed” (Source: hydrogencouncil.com)

Green Hydrogen CHP transition strategies

There are 2 main strategies to consider for Green Hydrogen CHP transition feasibility:

- Fully dependent on local Grid pipeline Hydrogen Blending plans.

- Onsite Green Hydrogen Production using Electrolyzers and Hydrogen Storage systems.

Choosing between one and/or the other depends on the local utility, current and future, electricity gas rates, emission factors, and the lifecycle cost comparison of a Battery VS Hydrogen Energy Storage System. A full feasibility study must be conducted that considers the above factors and numerous other factors which we elaborate on in an article titled CHP Feasibility | The perfect Building in the perfect Location.

In conclusion

Electrolysis is a leading hydrogen production pathway to achieve the Hydrogen Energy Earthshot goal of reducing the cost of clean hydrogen by 80% to $1 per 1 kilogram in 1 decade (“1 1 1”).” (Source: energy.gov)

Green Hydrogen produced via Electrolyzers operated via a Renewable resource will result in zero greenhouse gas emissions. However, the production cost needs to be decreased significantly to be competitive on average conditions (see Exhibit 6 above).

Green Hydrogen CHP systems might be cost competitive now (under optimal conditions), depending on a thorough feasibility study findings considering all factors affecting the lifecycle costs of the system.

If you’re looking to evaluate your Green Hydrogen CHP microgrid project, you must try our software, CogenS™. CogenS™ will help you design your CHP project in a fraction of the time spent on multiple screening, modeling, simulation, optimization and design tools. We managed to pull off an accurate design procedure that eases the process with preset automatically populated defaults, and simulation and modeling functions that does most of the work for you.